A) Resource recombination

B) Supply chain management

C) Production

D) Purchasing

F) All of the above

Correct Answer

verified

Correct Answer

verified

Multiple Choice

In ____________, materials are physically or chemically changed to produce a product.

A) process manufacturing

B) assembly processes

C) utilitarian production

D) diffusive manufacturing

F) A) and B)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

For the past two years, Mountain High Bike Company used suppliers from India, Japan, and Malaysia to provide them with precision parts for its custom bikes. There was only one problem: the quality of the parts from all locations lacked precision and consistency. Skilled technicians complained that as many as three out of five parts had to be discarded due to imperfections. The quality control manager convinced the owners to partner with a slightly higher-priced company in Omaha, Nebraska, which utilized _________________ to test samples of product components for deviations in quality and precision, prior to sending them to Mountain High Bike Company. The bike company realized savings in both time and money.

A) statistical process control

B) just-in-time inventory control

C) lean manufacturing

D) flexible manufacturing

F) A) and D)

Correct Answer

verified

Correct Answer

verified

True/False

Enterprise resource planning (ERP) is simpler and less sophisticated than manufacturing resource planning (MRP).

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Mass customization is not exclusive to product-intensive businesses. Service businesses have learned how to use mass customization to serve their customers.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Mini-Case "These are exciting times for our company. We've made a lot of changes over the past two years that have really improved our operations and lowered our costs. Now we are ready to expand into new markets. Minimotors is on its way to becoming a global player." The speaker was Sparky Weyer, president and CEO of Minimotors, Inc., a growing manufacturer of small (some of them downright tiny) electric motors used in a variety of power tools and appliances. Sparky was meeting with potential financial backers in an effort to obtain funding for some expensive new machinery he wanted to purchase. "You may have heard about some of the ways we've cut costs," Sparky continued. "We've developed a new arrangement with several of our biggest suppliers. They've agreed to make more frequent deliveries tied directly to our production schedules. This will help us reduce our inventory costs dramatically. We've also greatly reduced the number of defective motors we produce by carefully keeping tabs on all of our manufacturing processes. In fact, we have set a goal of reducing our defects to 3.4 parts per million. The main purpose of my meeting with you today is because we want to install some sophisticated new machinery and software that will allow us to quickly design and produce motors to the exact specifications of our customers. The machinery is computer-controlled and can produce custom-designed products at very little increase in cost compared to our mass-produced motors. We feel this flexibility and quick response time will give us a tremendous competitive advantage and help us attract new customers. Installing the new equipment and training our workers to use it properly will be a complex project, but I'm confident that once we get everything up and running we'll be able to strengthen our position as the leading maker of high-quality electric motors." -Sparky sees quality control in terms of detecting potential problems to prevent their occurrence and thus save Minimotors money. The quality control process that is most closely linked to Sparky's goal is known as:

A) Six Sigma.

B) Quality function deployment.

C) ERP.

D) PERT analysis.

F) None of the above

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Mini-Case "These are exciting times for our company. We've made a lot of changes over the past two years that have really improved our operations and lowered our costs. Now we are ready to expand into new markets. Minimotors is on its way to becoming a global player." The speaker was Sparky Weyer, president and CEO of Minimotors, Inc., a growing manufacturer of small (some of them downright tiny) electric motors used in a variety of power tools and appliances. Sparky was meeting with potential financial backers in an effort to obtain funding for some expensive new machinery he wanted to purchase. "You may have heard about some of the ways we've cut costs," Sparky continued. "We've developed a new arrangement with several of our biggest suppliers. They've agreed to make more frequent deliveries tied directly to our production schedules. This will help us reduce our inventory costs dramatically. We've also greatly reduced the number of defective motors we produce by carefully keeping tabs on all of our manufacturing processes. In fact, we have set a goal of reducing our defects to 3.4 parts per million. The main purpose of my meeting with you today is because we want to install some sophisticated new machinery and software that will allow us to quickly design and produce motors to the exact specifications of our customers. The machinery is computer-controlled and can produce custom-designed products at very little increase in cost compared to our mass-produced motors. We feel this flexibility and quick response time will give us a tremendous competitive advantage and help us attract new customers. Installing the new equipment and training our workers to use it properly will be a complex project, but I'm confident that once we get everything up and running we'll be able to strengthen our position as the leading maker of high-quality electric motors." -The equipment and software Sparky wants to acquire will allow the computers used to design motors to be linked directly to the computer-aided equipment on the factory floor. Sparky is proposing to set up a(n) :

A) modular manufacturing system.

B) computer-integrated manufacturing system.

C) E-hub that relies on network software to control the production process.

D) first-in, first-out production system.

F) All of the above

Correct Answer

verified

Correct Answer

verified

True/False

Over the past few years, Internet-based companies have emerged to help businesses find the best supplies at the best prices.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Operations management in service industries is about creating a good experience for the customer.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Process manufacturing involves taking raw materials and physically or chemically changing them into another form, while the assembly process takes the newly changed form and turns it back into the original form.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

One strategy U.S. manufacturers have employed in order to become more competitive is:

A) focusing on providing the lowest-priced products.

B) relying on advanced technology and the Internet to unite companies.

C) maintaining a distance relationship with suppliers in an effort to guard trade secrets.

D) increasing advertising budgets.

F) C) and D)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

To create their Deluxe Beef Sandwiches, Robbie's Roast Beef finely slices prime roast beef, stacks it on a sesame bun, adds special seasonings, cheese, onions, and mushrooms. The value added by Robbie's when it combines these ingredients to make a sandwich is known as:

A) consumer surplus.

B) the analytic function.

C) marginal utility.

D) form utility.

F) C) and D)

Correct Answer

verified

Correct Answer

verified

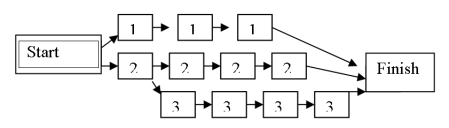

True/False

Review the PERT Network below: If it takes 2 weeks for each activity (represented by a box) to be completed, it can be determined that the boxes labeled with No.1 create the critical path because this path of activities takes the shortest time to complete.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Each day the general manager at the New Life Grocery Store reviews employee work schedules, including the late night stock crew, the checkers, the baggers, the deli, produce, and meat department crews, and the office personnel. He coordinates work schedules with shipments, as well as the information he collects from registers that indicates the busiest hours at the store, and then he communicates any exceptions to his department managers. These daily tasks are part of ______________.

A) operations management

B) promotions management

C) distributive management

D) marketing management

F) None of the above

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Last week John got a call from his contact Eric at Alpine Telecomm in Switzerland, one of his company's largest international customers. As Eric put it, "This is a heads-up! Top management is asking operations to review our vendors for ISO 14000 compliance." John's company should prepare to demonstrate:

A) an acceptable level of quality standards of the products and services it provides.

B) a level of quality in its products and services that exceeds its competitors.

C) a world-class management system in information technology and lean manufacturing.

D) best practices for managing its impact on the environment.

F) A) and C)

Correct Answer

verified

Correct Answer

verified

True/False

In a just-in-time inventory system, the producer holds large quantities of the materials and components used in the production process in its inventory to ensure that it always has enough on hand.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

One key to the resurgence of U.S. firms as world-class competitors has been the implementation of a focus on quality.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

X-Sport Industries is a U.S.-based manufacturer of sporting goods. Recently, it has decided to make a major push to sell its products in the European Union. In order to succeed in this new market X-Sport will need to:

A) become certified in ISO 9000 standards.

B) convert its financial assets into euros.

C) avoid reliance on the Deming cycle.

D) reduce the wages of its production workers.

F) A) and B)

Correct Answer

verified

Correct Answer

verified

True/False

The U.S. is still manufacturing intensive. Only 25% of U.S. jobs come from the service sector.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Land, labor, capital, and knowledge are inputs into the production process.

B) False

Correct Answer

verified

Correct Answer

verified

Showing 21 - 40 of 326

Related Exams